PLASMA SPRAY COATING LABORATORY

A cutting-edge technology for coating applications, utilizing ionized gases to thermally melt and propel coating materials onto substrates, ensuring strong adhesion and superior surface properties. Designed for industries requiring robust coatings in aerospace, automotive, and energy sectors, offering enhanced material performance and durability.

Our laboratory employs advanced plasma-based methodologies for the production of:

- Thermal Barrier coatings

- Exfoliation of 2D materials

- Tailoring wettability of coatings

- Graphene coatings

- Corrosion-resistant coatings

- Wear resistant coatings

- Nitride coatings

- Water filtration membranes

Plasma Spray Gun (9MB, Oerlikon Metco, Switzerland)

Specification:-

Maximum Power: 80 kW

Gases: Argon, Hydrogen, Helium, Nitrogen etc.

9MC Control Unit

Specification

- Rotameter gas metering system

- Real-time monitoring of process parameters

- Automatic operation of a wide range of plasma spray guns

- Easy-to-read LED message and alarm display

- Centralized monitoring of system status and conditions

- Multisystem operation; master / slave configuration capability

- Interfaces for workpiece handling equipment, gun

10 MR

It provides up to 100 kW of DC power, a continuous duty cycle, which is required by the plasma spray gun in a MetcoTM 9MC plasma spray system. The 10MR maintains a constant current value during spray operations with low voltage variation, so coating parameters are quickly established and repeatable coating results obtained.

DUST COLLECTOR

Dust collectors play a crucial role in plasma spray processes by capturing and removing airborne particles generated during the spraying of materials. These particles include fine powders, droplets, and debris that are produced when the plasma spray gun melts and propels the feedstock material onto the substrate. The dust collector helps to ensure a clean working environment, prevent contamination, and maintain operator safety.

GRIT BLASTING SETUP

A surface preparation technique commonly used before plasma spraying and other thermal spray processes. It involves propelling abrasive particles (grit) at high velocity onto a surface to clean it, remove contaminants, and create a rough texture. This prepares the surface for the subsequent plasma spraying process

ACCURASPRAY

Accuraspray measures the inline spray plume temperature, velocity, dimension, orientation, intensity and stability.

Specification

| Particle temperature range |

1000°C and higher at 3% accuracy 1832°F and higher at 3% accuracy |

| Particle velocity range |

5 - 1200 m/s at 2% accuracy 15 - 4000 ft/s at 2% accuracy |

| Spray plume intensity and peak height | 2% accuracy |

| Spray plume width and position |

0.1 mm accuracy 0.004 in accuracy |

| Spray angle | 0.2 degree accuracy |

| Substrate temperature pyrometer |

From 0 to 500°C From 32 to 932 °F |

| Process stability | Automatic instability detection |

METALLOGRAPHIC AND CORROSION LAB

HIGH SPEED SAW

A precision cutting tool to achieve rapid and precise cutting through hard materials with exceptional efficiency. Ideal for applications demanding swift, clean, and accurate cuts.

LOW SPEED DIAMOND SAW

For controlled and meticulous cutting, employing diamond-coated blades to ensure gentle material sectioning with minimized heat generation. Designed for tasks requiring careful precision and reduced risk of sample deformation.

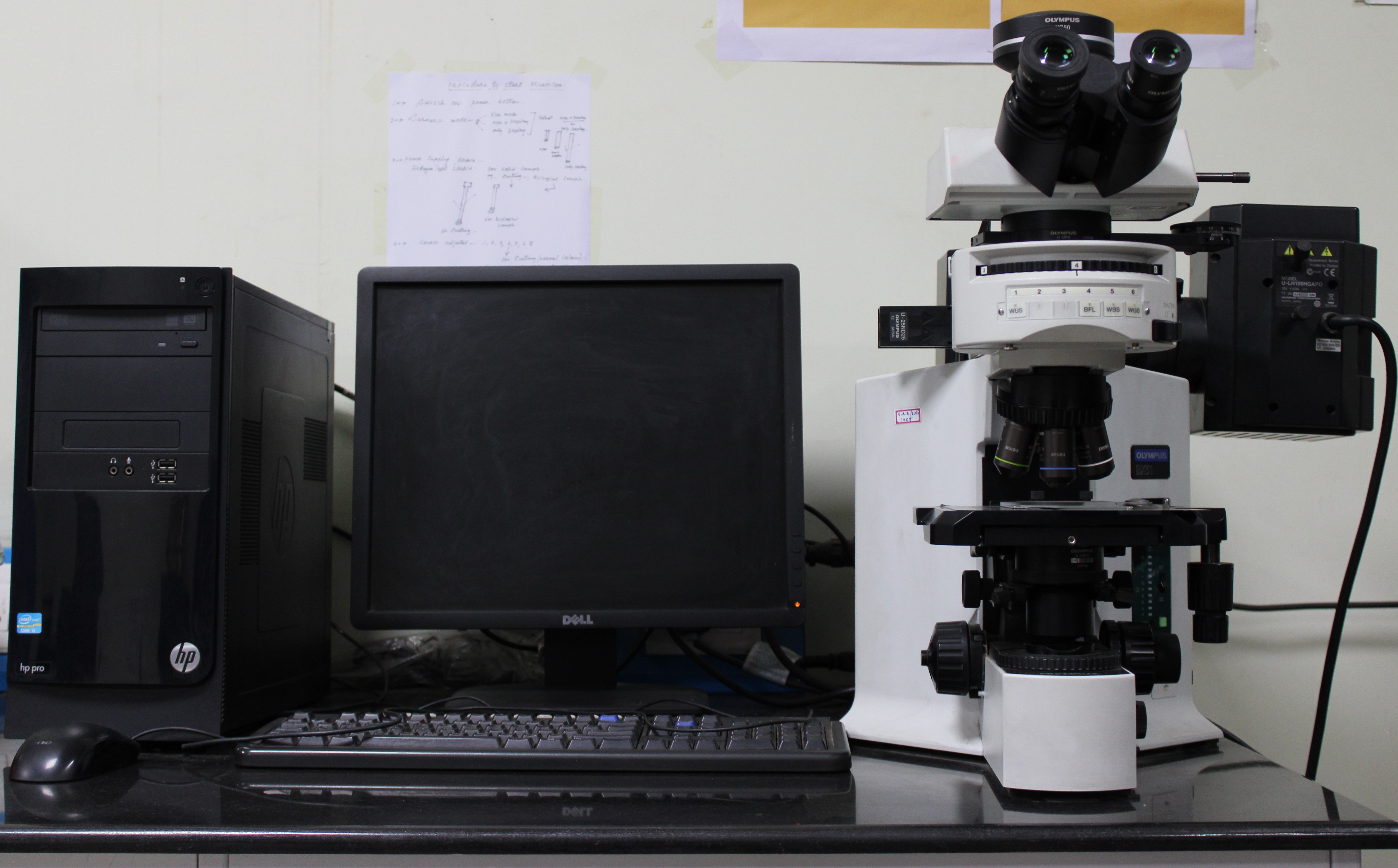

OPTICAL MICROSCOPE

An imaging instrument equipped with high-resolution lenses and adjustable magnification, enabling detailed visual analysis of microscopic samples for scientific research and educational purposes. Ideal for observing intricate structures and analyzing diverse materials with clarity and accuracy.

GAMRY INSTRUMENT/ CORROSION TEST SETUP

A sophisticated electrochemical system enabling precise evaluation of corrosion behavior, featuring customizable electrochemical techniques and advanced data analysis tools. Engineered for comprehensive corrosion studies in diverse environments, offering insights into material durability and protection strategies.

Specification

- To study a variety of electrochemical system

- Gamry's range of potentiostats can perform cyclic voltammetry from sub-pA to As of

- current and scan rates from sub-mV to thousands of volts per second

- Measure double-layer capacitance or electrochemical surface area (ESCA) during CV.

GRINDING AND POLISHING

A grinding and polishing machine is equipped with variable speed settings, offering versatile material refinement through sequential grinding and polishing stages.

TRIBOMETER

An advanced instrument designed for studying friction and wear behaviour at elevated temperatures, combining precise load control with an integrated furnace for accurate simulation of real-world conditions. Tailored for investigating material interactions under extreme thermal environments, offering insights into various industrial applications.

Specification

- Measuring friction, wear, and material mechanical properties is a way for engineers to understand how materials, coatings, and lubricants will stand up to the rigors of varied applications, from heavy industry to semiconductor, from automotive to biomedical

- Load Range Nano, Micro, Macro

- 0 °C to 800 °C

- Modular with Interchangeable Modules

- Coatings, Lubricants, Materials Surface and Tribology Studies

HEAT TREATMENT LAB

VACUUM OVEN

An essential apparatus to create a controlled environment of reduced pressure, enabling processes that require precise temperature regulation, drying, and heat treatment of samples. It is particularly valuable when working with delicate or heat-sensitive materials that could be compromised under normal atmospheric conditions. Equipped with temperature controls, a vacuum pump, and a sealed chamber, the vacuum carefully remove moisture, solvents, and gases from samples while maintaining their structural integrity. This can aid in the preservation of product quality and the prevention of unwanted reactions.

HOT AIR OVEN

A reliable laboratory equipment designed for consistent heating and drying of samples, featuring adjustable temperature settings and even air circulation.

Specification

- Used in heat treatment and drying of samples, such as metals, alloys, powders, and other materials

HIGH TEMPERATURE FURNACE

An advanced thermal chamber designed to achieve and maintain elevated temperatures for material processing and testing, offering precise temperature control and uniform heat distribution.

Specification

- High-temperature furnaces as tabletop or floor-standing models for maximum temperatures between 1550 °C and 1800 °C, for example, to melt glass and develop new technical glass products.

- Used for high-temperature heat treatments to remove binder, metal and ceramic sintering

- parts curing and melting through:

- Annealing

- Sintering

- Melting

- Binder burnout

- Curing

MECHANICAL TESTING AND SAMPLE PREPARATION LAB

ADHESION TESTER

A robust instrument designed to measure the adhesive strength of coatings by applying controlled axial force, providing quantitative assessments of bond integrity. It evaluates the adhesion (pull-off strength) of a coating by determining the greatest tensile pull-off force that it can bear before detaching.

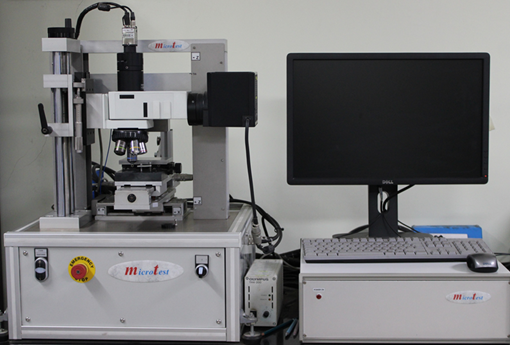

INSTRUMENTED HARDNESS AND SCRATCH TESTER

A versatile equipment for assessing material hardness and scratch resistance, offering precise load and depth control. Enables comprehensive characterization of material properties for research, development, and quality assurance purposes.

Specification

- High-temperature furnaces as tabletop or floor-standing models for maximum temperatures between 1550 °C and 1800 °C, for example, to melt glass and develop new technical glass products.

- MICROTEST MTR3 systems are used to study

- Dislocation behaviour in metals

- Fracture behavior in ceramics

- Mechanical behavior of thin films and bone

- Residual stresses

- Time dependent behaviour in soft metals and polymers

PLANETARY BALL MILL

A high-performance milling device offering simultaneous rotational and revolution motion for efficient mixing and particle size reduction.

HELIUM GAS PYCNOMETER

A precision instrument employing helium displacement to measure the true volume and density of solid materials, enabling accurate characterization of porosity and density with exceptional sensitivity.

Specification

Measure the true density of solid samples using an inert gas to measure the sample volume by applying Archimedes’ principle of displacement. Do not affect the surface chemistry or physical structure of the sample during measurement Measures up to five samples sized from 1 cm³ to 135 cm³ with the highest level of accuracy due to its multiple built-in expansion volume chambers.

HALL FLOW METER

A standardized device designed to assess the flowability of powdered materials, employing a funnel mechanism to quantify the flow rate through an orifice.

SURFACE ROUGHNESS TESTER

A device used to measure the texture or roughness of a surface at a microscopic level. It provides quantitative information about the deviations in the surface profile.

SPRAY DRYER

A versatile industrial equipment designed to convert liquid solutions into dry powders through atomization and rapid evaporation, enabling controlled particle size and consistent product characteristics.

Specification

- Used to dry into powder from the solution or paste liquid

- The original essence of material will not be changed after drying

- Instant dry, short drying time

- Optional equipment for different product feature

- Able to dry high viscosity and concentration liquid

CENTRIFUGE

An instrument used to separate components of a liquid mixture based on their density and sedimentation rates.

ULTRASONICATOR

An equipment used for various applications such as cleaning, degassing, mixing, emulsifying, and dispersing. It uses high-frequency sound waves (ultrasound) to create cavitation bubbles in a liquid, which then collapse, generating high-intensity localized energy that can effectively clean or process materials